|

|

|

|

With the equipment at our facility, such as high-shear mixing equipment,

we can develop almost any type of skin-care product. Accelerated stability testing ovens, a Brookfield viscometer,

and other analytical instruments are available for evaluating the formulas

that are developed. We also have the following cutting-edge analytical

equipment:

|

|

|

|

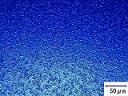

Direct

observation of dispersed particles in emulsions is a useful way to determine

the stability of a product. When using conventional transmission microscopes

and reflection microscopes, the thickness and reflectivity of a sample can make

it difficult to adjust the focus, resulting in blurred images. Our video microscope,

developed especially for the cosmetics field, overcomes the drawbacks of

conventional microscopes and produces clear images of emulsion particles.

|

|

Recent advances in emulsification

technology have led to the development of functional emulsions, including gel

networks. The structure of the gel network contributes to the stability of the emulsion

and also helps to improve its texture and its ability to hydrate the skin.

Using our video microscope, the structure of these gel networks can be visualized.

|

|

|

|

|

A rheometer measures and evaluates

the rheology of a substance—that is, how it deforms and flows when stress is

applied. The texture of emulsion products, such as creams and milk lotions, is strongly

associated with their rheology. For example, creams and milk lotions dramatically

lose their viscosity under certain stresses. The degree of such stress is

correlated with the texture of the product at the instant of starting to smooth

it on, and might lead, for example, to it being described as having a “gracefully

gentle touch”. In addition, most emulsions have thixotropic properties, which

also affect their texture while being smoothed onto the skin, and might lead,

for example, to the product being described as “melting into the skin”. Analyzing

the rheology of an emulsion can offer insights into its texture when applied to

the skin. Measuring the rheology of a product also elucidates its emulsion

structure, which helps in evaluating the product’s stability.

|

|

|